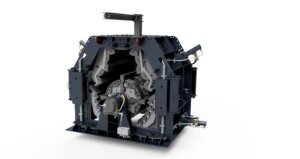

Introducing the Groundbreaking HAZEMAG VR4 Rotor – a genuine game-changer

Building on the success of the highly effective VR2 rotor, which was renowned for its exceptional wear resistance and impressive performance in tertiary crushing for sand production, HAZEMAG has now taken innovation to the next level with the development of the VR4 rotor.

The Inventor of the Impact Crusher Presents the VR4 Rotor

As the inventor of the impact crusher, HAZEMAG has been originating groundbreaking developments in crushing technology for decades and, with the VR4 Rotor, we once again demonstrate our leadership and unrivalled expertise. Years of experience, and a thorough understanding of impact crusher technology, enable us to develop innovative, bespoke solutions to meet our customers’ needs.

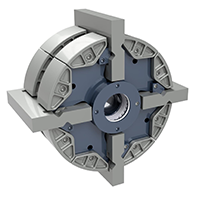

Symmetrical Design with Advanced Features

The VR4 Rotor is a symmetrical masterpiece, seamlessly integrating the wear-resistant features of the VR2 rotor, including symmetrically-designed and strategically-positioned wear caps and high-quality blow bars, with the robustness and engineering brilliance of its predecessors: the four-blow bar rotors – a testament to their enduring efficacy over decades. The primary objective during the development phase was to enhance customer benefits, and the result speaks for itself. This innovative rotor design significantly enhances operational availability and elevates maintainability to a new level.

Innovative Integration of Wear Caps and Blow bars

What sets the VR Rotor apart is the integration of solid, cast wear caps and specialised blow bars. These caps and blow bars deliver a substantial increase in wear mass, rendering the expensive process of hardfacing within the machine obsolete. Now, if there is excessive wear area ahead of the blow bar, simply loosening a screw allows for the quick replacement of wear caps and blow bars; making maintenance a breeze. The ingenious arrangement and structure of the wear caps and blow bars enable them to be interchanged, ensuring optimal utilisation of the wear mass. This novel wear part concept not only guarantees ergonomic and safe working at all times, but also drastically reduces maintenance and repair times – reducing downtime to an absolute minimum.

Blow Bar Optimisation

The integration of wear caps and blow bars not only enhances the functionality of the rotor, but also optimises the blow bar itself. Using a proven locking mechanism, blow bars are now securely attached externally; effectively extending the blow bar, whilst retaining the same rotor tip diameter. This delivers a significant advantage in terms of increased wear mass, and the improved geometry also allows for blow bars to be rotated twice. In addition, if you’re looking for even greater wear resistance and extended service life, optional ceramic inserts for the blow bars are also available.

Multiple Size Options

To ensure a perfect fit for numerous configurations, HAZEMAG VR Rotors are offered in a range of sizes, including: 1005mm, 1007mm, 1010mm and 1014mm. Versatility is the key feature, as these rotors can be integrated seamlessly into all HAZEMAG impact crushers within the respective size range.

The Future of Crushing Technology

Embrace the potential of wear caps and specialised blow bars, and experience the future of crushing technology today with the HAZEMAG VR4 Rotor – a powerful fusion of innovation, durability, and efficiency for a superior crushing performance.

HAZEMAG – redefining industry standards, revolution after revolution!