Key Features

UNIROTOR VARIO HUV

TECHNICAL DATA

UNIROTOR VARIO HUV

| Type | Capacity* [mt/h] | max. edge length of lump [mm] | Inlet height x width [mm] | Installed Power* [kW] | Weight [kg] |

| HUV 1013 | 110 | 120 | 430 x 1220 | 315 | 10.000 |

| HUV 1020 | 180 | 120 | 440 x 1910 | 450 | 13.500 |

| HUV 1313 | 115 | 220 | 376 x 1.240 | 315 | 15.000 |

| HUV 1622 | 360 | 280 | 690 x 2150 | 900 | 38.000 |

| HUV 1626 | 390 | 280 | 690 x 2600 | 1.000 | 43.000 |

| HUV 1630 | 450 | 280 | 690 x 3000 | 1.200 | 48.000 |

| HUV 1634 | 510 | 280 | 690 x 3400 | 1.300 | 53.000 |

| * medium-hard limestone 95%< 6mm - values are variable and can be aligned to the particular requirements. | |||||

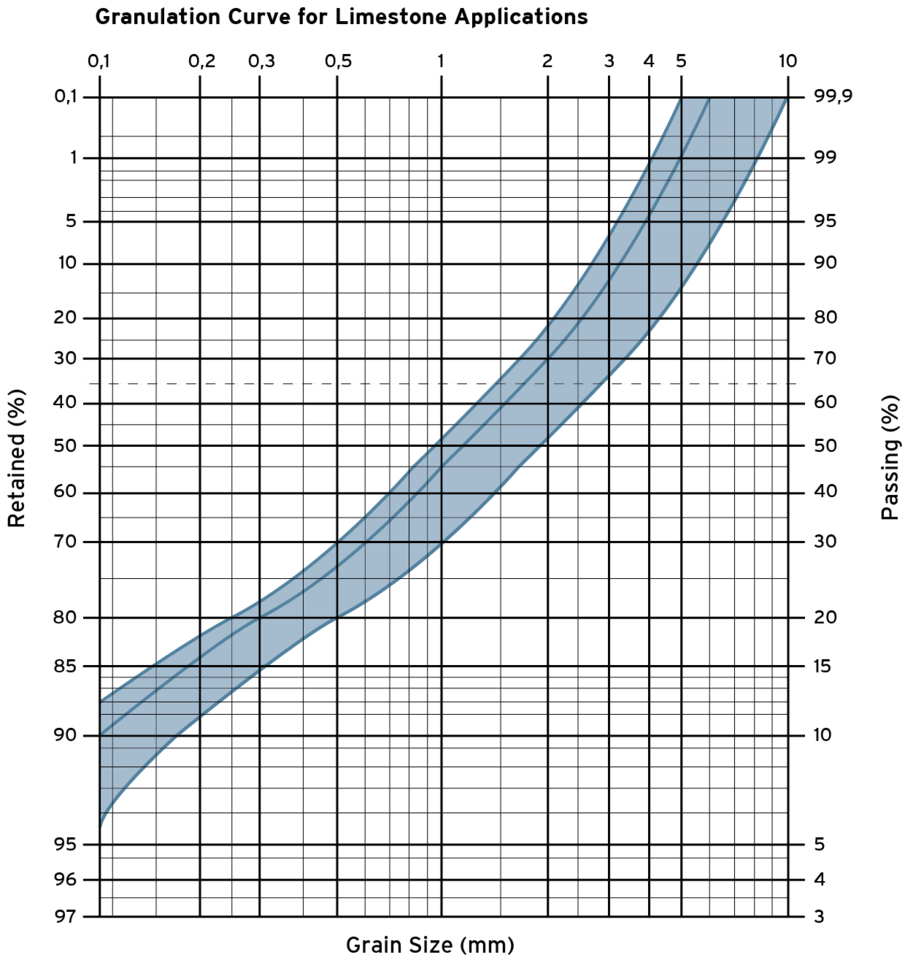

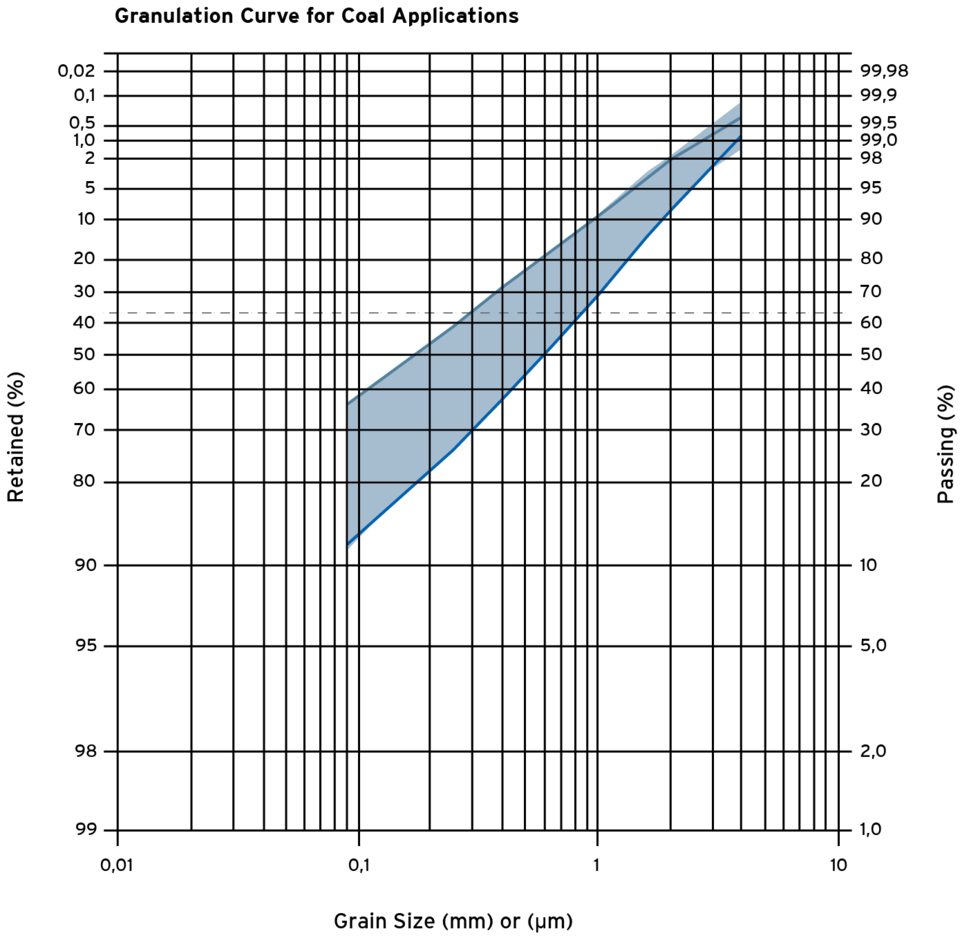

Granulation Curves

PRODUCT DESCRIPTION

HAZEMAG’s HUV Hammer Mills are mainly used in the raw materials sectors, and the iron and steel industry, for secondary and tertiary crushing of various materials. They are often employed for the fine crushing of medium-hard to soft materials such as anhydrite, quicklime, lignite, coal, oil shale, dolomite, chalk, gypsum, glass, clay, limestone, etc

The feed material, which is conveyed to the processing chamber, is crushed through impact as well as through attrition. Impact stress occurs at the inlet, but the crushed material is mainly comminuted through blows by the retracting effect of the rotor in the lower part of the narrowing crushing chamber. The material remains in the workspace until it is discharged through the grate gaps or opening section. The grinding path restricts the amount of oversize and supports the generation of a cubical and stress-free product.

The HUV Hammer Mills are designed in such way that they can be driven at both continuous or variable rotor speeds. Inspection flaps and hinged housings are provided to facilitate easy maintenance, and allow access to all wear parts and grindings paths.

The torsion-free mill casing is protected against wear through bolted-on lateral plates of wear-resistant material and, being mounted on an anti-vibration base frame, mostly reduces dynamic loads. The two sides of the mill housing can be opened or closed hydraulically.

A vital component of the HAZEMAG Hammer Mills is the disc-type rotor, to which the moving hammers are mounted. The heavy-duty rotor is of a steel disc design, with free moving (360°) hammers mounted between the discs. It is shaft mounted and fitted with self-aligning roller bearings. The rotor can also be operated in both directions; optimising utilisation of the hammers and eliminating the need to turn them manually. Hammers are made of compound castings, which are easy to exchange, and the finely balanced design of the opposing hammers ensures balanced running. The flexible suspension of the hammers on the rotor ensures that the HUV Hammer Mill is robust enough to withstand the intrusion of extremely hard foreign particles.

Reversible and non-reversible rotor

On the reversible version, the hammers can be utilised to their optimum by reversing the direction of drive without having to reverse the heads themselves. On the non-reversible HUV, only one grinding path can be used. Instead of the grinding path, a curved plate is installed to protect the housing.

The HUV can be driven at either a constant or a variable speed.

All HAZEMAG HUV Hammer Mills are equipped with a rotor turning device – allowing the rotor to be moved and locked in the appropriate position for safe and easy hammer replacement.

The rotor turning device comprises a worm gear with hydraulic drive and brake.

For fine product, an optional grate basket can be fitted, with grate bars built into the grate basket. This assembled unit gives the built-in grate bars the necessary mechanical stability and at the same time fixes the grate bar width required to generate a specific product size. In and out movement of the grate basket carrier is controlled hydraulically.

Grinding paths can be supplied with a heating system fitted. Heated impact walls can improve material flow when processing feed materials, containing a certain amount of moisture, which have a tendency to cake. Heat-conducting oil is pumped through a pipework circuit installed behind the grinding paths, and the rear face of the heated pipework is appropriately insulated.