Key Features

SECONDARY IMPACTOR HSI

TECHNICAL DATA

SECONDARY IMPACTOR HSI

| Rotor | Inlet | Capacity | Hard Rock | Soft to Medium Hard, Low Abrasion | |||||||||

| Type | Dia. x Width mm | Height x Width mm | 95% <45mm t/h | Max. Edge Length mm | Power Requirement kW | Weight kg | Max. Edge Length mm | Power Requirement kW | Weight kg | ||||

| HSI 1007 | 1.030 x 670 | 495 x 690 | 40 - 90 | 180 | 75 - 110 | 6.800 | 300 | 45 - 90 | 5.950 | ||||

| HSI 1010 | 1.030 x 1.000 | 495 x 1.020 | 90 - 120 | 180 | 110 - 160 | 9.050 | 300 | 90 - 132 | 7.200 | ||||

| HSI 1014 | 1.030 x 1.340 | 495 x 1.360 | 120 - 160 | 180 | 160 - 200 | 10.700 | 300 | 132 - 160 | 9.300 | ||||

| HSI 1414 | 1.340 x 1.340 | 580 x 1.360 | 160 - 300 | 220 | 200 - 355 | 16.500 | 350 | 160 - 320 | 13.200 | ||||

| HSI 1420 | 1.340 x 2.000 | 580 x 2.020 | 300 - 420 | 220 | 355 - 500 | 23.000 | 350 | 315 - 400 | 19.800 | ||||

| HSI 1625 | 1.540 x 2.500 | 710 x 2.520 | 400 - 600 | 280 | 630 - 800 | 35.000 | 450 | 400 - 600 | 31.000 | ||||

| HSI 1630 | 1.540 x 3.000 | 710 x 3.020 | 600 - 700 | 280 | 800 - 950 | 42.000 | 450 | 630 - 710 | 37.200 | ||||

SECONDARY IMPACTOR HSI WITH GRINDING PATH

| Rotor | Inlet | Capacity | Hard Rock | Soft to Medium Hard, Low Abrasion | |||||

| Type | Dia. x Width mm | Height x Width mm | 95% <35mm t/h | Max. Edge Length mm | Power Requirement kW | Weight kg | Max. Edge Length mm | Power Requirement kW | Weight kg |

| HSI 1007 | 1.030 x 670 | 495 x 690 | 40 - 90 | 180 | 90 - 132 | 6.950 | 300 | 55 - 110 | 6.100 |

| HSI 1010 | 1.030 x 1.000 | 495 x 1.020 | 90 - 120 | 180 | 132 - 200 | 8.500 | 300 | 110 - 160 | 7.350 |

| HSI 1014 | 1.030 x 1.340 | 495 x 1.360 | 120 - 160 | 180 | 200 - 250 | 10.900 | 300 | 160 - 200 | 9.500 |

| HSI 1414 | 1.340 x 1.340 | 580 x 1.360 | 160 - 300 | 220 | 250 - 400 | 16.800 | 350 | 200 - 355 | 13.500 |

| HSI 1420 | 1.340 x 2.000 | 580 x 2.020 | 300 - 420 | 220 | 400 - 630 | 24.000 | 350 | 355 - 500 | 20.800 |

| HSI 1625 | 1.540 x 2.500 | 710 x 2.520 | 400 - 600 | 280 | 710 - 900 | 36.000 | 450 | 500 - 710 | 32.000 |

| HSI 1630 | 1.540 x 3.000 | 710 x 3.020 | 600 - 700 | 280 | 900 - 1.000 | 43.500 | 450 | 710 - 900 | 38.700 |

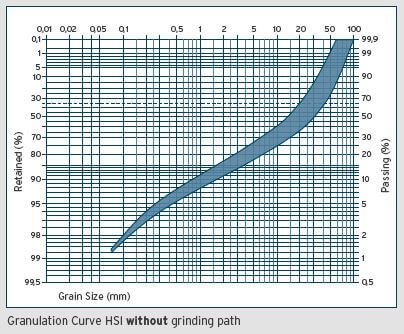

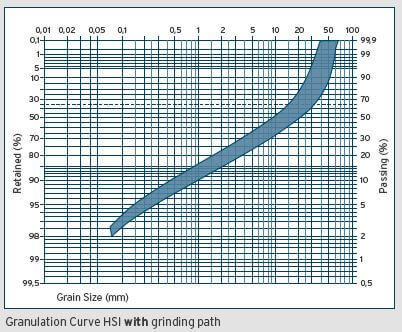

Granulation Curves

PRODUCT DESCRIPTION

HAZEMAG redefines secondary crushing technology…

The new HAZEMAG concept combines the knowledge gained from over 70 years of crusher design and manufacture, with the practical experience and operational needs of plant operators. The HSI series of secondary impactors have been designed for economic crushing and, depending on how the equipment is configured, are capable of processing either soft, medium-hard or hard rock.

This modular system provides the capacity to accomplish all the tasks and duties demanded by the bulk goods industry. All equipment and controls can be adapted to meet individual customer requirements, and even fully-automatic operation can be specified.

Depending on the feed material, the crushing ratio, and the desired product grain size, feed material sizes of up to 450mm can be accommodated, and throughput rates of up to 700 tonnes per hour can be achieved.

The rotor is the ‘heart’ of a secondary impact crusher, and the strength of this key component is tested relentlessly by the crushing process. Throughout HAZEMAG’s experience of over 70 years of in the industry, special emphasis has always been placed on rotor design, development, and the field of application.

The optimum rotor type for a crushing process is selected based on feed material characteristics and size reduction requirements. Secondary crushing requires a robust, heavy-duty rotor and torsion-free rotor body, to provide a high moment of inertia. The latest secondary rotors from HAZEMAG are engineered and manufactured as a welded steel construction, where individual discs are joined together, using a unique process, to form the rotor body. The impact elements – commonly referred to as hammers or blow bars – are located in holders on the rotor body and securely locked in position with wedges which can be easily removed for blow bar replacement.

The secondary crusher housing is a rugged, fabricated steel plate construction with heavy external bracing for increased strength and stability. For quick and easy inspection of the internal wear parts, the housing is fitted with large doors which are opened and secured by a special mechanism.

The rear housing section opens hydraulically to allow full access to the internal wear parts and, to ensure user safety when the housing is opened for maintenance, the weight is transferred through its centre to prevent it from closing inadvertently.

The Secondary Impactor HSI is equipped with a locking system, in accordance with European machinery directive 2006/42/EC, which must be integrated into the customer’s plant control system.

With simplicity and functionality in mind, the housing is fitted with replaceable, and interchangeable, wear-resistant liners. The liners are manufactured to a common design which allows approximately 95% interchangeability. A worn liner, for example, can be repositioned from a high wear zone (within the rotor circle), to a low wear zone (outside the rotor circle) – increasing utilisation of the wear metal and extending service life. The standardised design of the housing liner system also helps to reduce the operating costs of the secondary crusher.

Front Impact Apron

The front impact apron (primary impact zone) is a heavy-duty component, equipped with replaceable, bolt-on impact plates. HAZEMAG impact plates offer extended service life, and are fabricated to a standardised uniform shape to reduce spare parts stockholding levels.

Rear Impact Apron

The rear impact apron (secondary impact zone), similar to the front impact apron, is a heavy-duty fabricated component, is also equipped with replaceable bolt-on impact plates, and offers the same benefits of service life and flexibility.

Hydraulic suspension of the impact aprons

The hydraulic suspension of the impact aprons guarantees simple and quick adjustment of the opening widths and also provides overload protection. As soon as crushing forces in the crushing chamber exceed a predefined limit value, the impact aprons retract to protect the built-in parts, such as rotor, blow bars and impact aprons, from potential damage. After the retracting procedure the impact aprons move back to their original position, in a controlled manner, so that the crushing operations can continue without interruption.

In addition, the hydraulic impact suspension mechanism also offers the convenient option of simple readjustment and quick adaptation to fluctuations in process conditions; either directly at the machine on-site, or from the plant control room.

As a fitted option, the HSI series can be supplied with a grinding path.

The grinding path is designed as a series of impact steps (grinding beams/bars) which ensures limited oversize production, provides an excellent level of control over product grading, and delivers a reliable, stress-free, cuboidal product.

The replaceable grinding beams are manufactured from high-chromium steel, and the grinding path is set and adjusted via external hydraulic cylinders.

With the HAZtronic® system, a HAZEMAG Secondary Impactor HSI can be monitored and adjusted remotely from the control room to deliver optimum productivity. All settings that determine the end product can be called up and regulated at the touch of a button, without interrupting operation; ensuring immediate action can always be taken, and adjustments made, to suit varying operating conditions.

The HAZtronic® system monitors and visually displays apron positions, bearing temperatures, hydraulic fluid temperatures and fluid levels. With simplicity in mind, optimising the performance of the HSI Impact Crusher is enhanced by a touchscreen control panel, and opening the impactor housing, or adjusting the impact aprons, is all achieved at the touch of a button.

HAZEMAG HSI Impactors achieve a level of performance and economical operation that remains second to none!

- AP-S

- AP-SM

- AP-SMH

- AP-KH

- AP-KMH